Adria 40 & MAN Diesel Engine Service & Repairs Worldwide: 60 years of experience

To whom it may concern:

We would like to offer the following products:

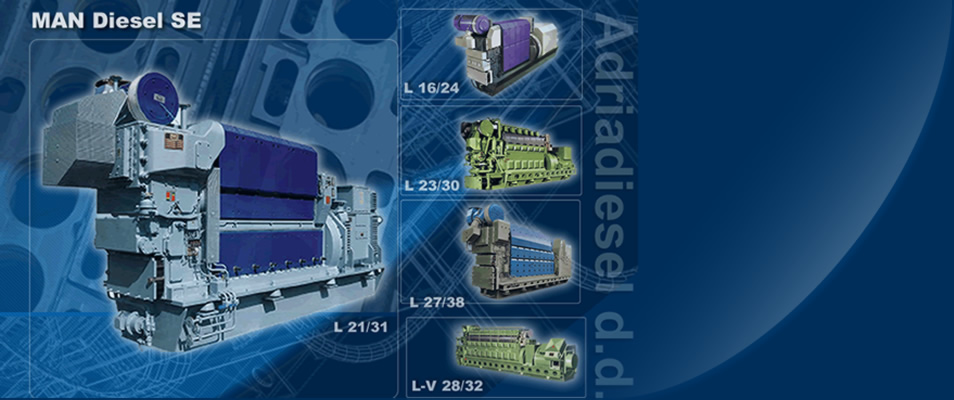

- Medium-speed four-stroke MAN engines (500 kW – 3000 kW)

- Large / ADRIA-40 engine (6.3 MW)

- CPP (containerised power plants / diesel-powered generators) (500 kW)

and services:

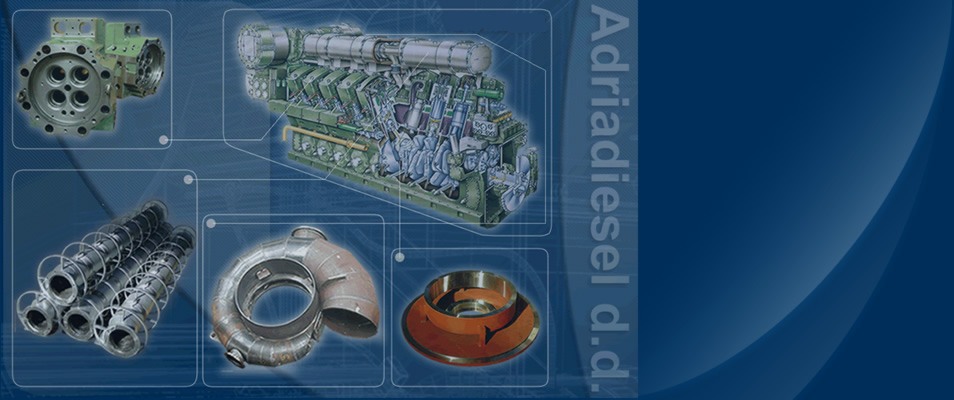

- spare parts for Adria 40 and MAN diesel engines

- troubleshooting, maintenance, service and repair of Adria 40, MAN and other diesel engines and other power plants

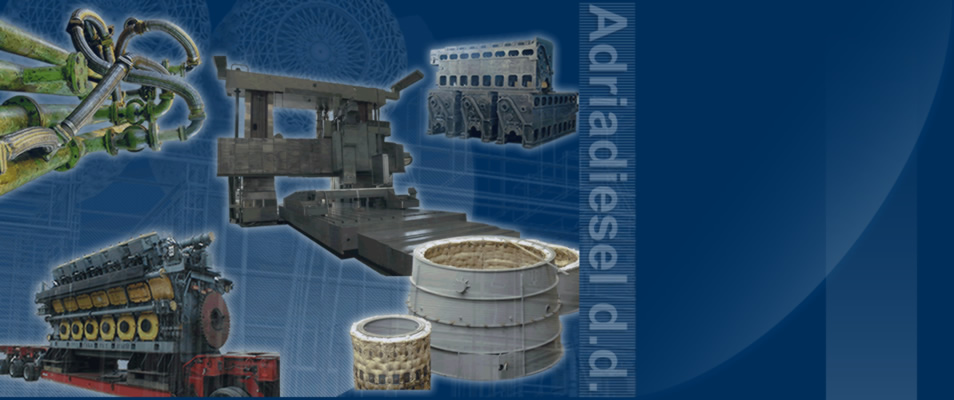

- diesel engine overhaul

- machining and heat treatment services

- full range of ship-repair services, alongside or in floating docks, in co-operation with the Service Centre Trogir of Shipyard Brodotrogir

A few words about us:

In 1949 as a part of the large industrial complex “Jugoturbina”, the company “Tvornica diesel motora” (Diesel Engine Factory) was established. We have been operating under the name of “Adriadiesel” since 1991.

Our factory has been producing engines under the “Sulzer (Switzerland) license” from 1955 until 1998, and has been producing engines under the “MAN (Germany) license” from 1998. Since the establishment of the company, during the 60 years of its existence, more than 1580 engines with more than 2,000 MW of power have been produced and delivered to more than 50 countries worldwide.

Adriadiesel brochures, company profile - you can view the materials at this link. You can view the specifications of various engines at the following link.

We would like to become your prime choice for providing the mentioned services and products because of our quality, experience and price-competitiveness.

Please send us your enquiry or request for quotation and we will send you our best prices.

Feel free to contact us for any additional information.

Best regards,

Nenad Končar, PhD

Managing Director

Adriadiesel d.d.

This email address is being protected from spambots. You need JavaScript enabled to view it.

This email address is being protected from spambots. You need JavaScript enabled to view it.